Fiberglass reinforcement plays a critical role in modern composite materials, widely used across industries such as marine, construction, automotive, wind energy, and industrial manufacturing. Among the most commonly used reinforcements are fiberglass mat and fiberglass cloth. While both are made from glass fibers, their structure, performance, and applications differ significantly. Understanding these differences is essential for selecting the right material for strength, durability, and cost efficiency.

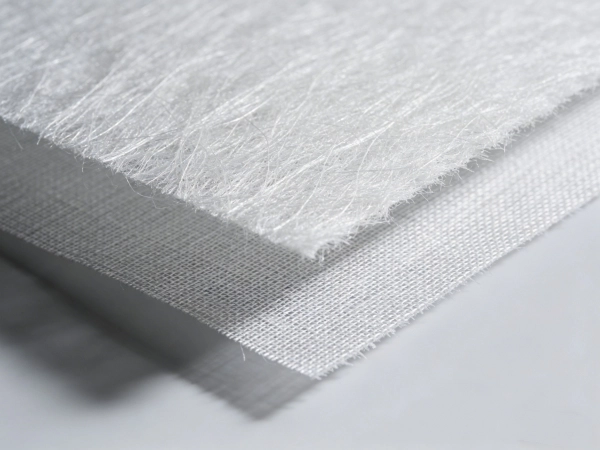

The primary difference between fiberglass mat and fiberglass cloth lies in fiber arrangement and bonding method.

Fiberglass mat, often referred to as chopped strand mat (CSM), is composed of randomly oriented short glass fibers held together by an emulsion or powder binder. This non-woven structure allows the fibers to distribute in multiple directions, creating relatively uniform strength in all orientations. The random layout also enables the mat to conform easily to curved or complex molds.

In contrast, fiberglass cloth is a woven fabric made from continuous glass filaments arranged in an orderly pattern, such as plain weave, twill weave, or satin weave. This woven structure provides directional strength, meaning the material is strongest along the warp and weft directions. Fiberglass cloth is more uniform in thickness and offers higher structural consistency.

From a structural standpoint, fiberglass mat emphasizes isotropic reinforcement and mold conformity, while fiberglass cloth focuses on controlled fiber alignment and load-bearing efficiency.

When tensile strength is a key requirement, fiberglass cloth generally outperforms fiberglass mat.

The continuous fibers in fiberglass cloth remain intact across the length of the fabric, allowing loads to be transferred more efficiently through the material. This results in higher tensile strength, improved stiffness, and better resistance to stretching and deformation. As a result, fiberglass cloth is commonly used in applications that demand structural integrity, such as boat hulls, panels, load-bearing components, and high-performance composites.

Fiberglass mat, due to its chopped fibers, exhibits lower tensile strength. While it provides good overall reinforcement and impact resistance, the discontinuous fibers limit its ability to withstand sustained tensile loads. However, fiberglass mat still plays an important role as a supporting or secondary reinforcement layer, especially when combined with woven fabrics.

In summary, fiberglass cloth is the preferred choice for strength-critical applications, whereas fiberglass mat is suitable for non-structural or supplemental reinforcement.

In terms of handling and installation, fiberglass mat is generally easier to work with, particularly in manual fabrication processes.

Fiberglass mat cuts easily with basic tools and adapts well to irregular shapes, corners, and complex contours. Its random fiber orientation allows it to lay flat against molds without wrinkling, making it ideal for hand lay-up processes and repairs. Additionally, fiberglass mat absorbs resin quickly, which simplifies wet-out during lamination.

Fiberglass cloth, while still manageable, requires more careful handling. The woven fibers can fray at cut edges, and the fabric may resist conforming to tight curves without precise placement. Achieving proper resin saturation may also take longer, especially with heavier weaves.

For projects prioritizing ease of installation and mold adaptability, fiberglass mat offers clear advantages. Fiberglass cloth, however, rewards careful installation with superior mechanical performance.

Fiberglass mat is the better option in several specific scenarios:

• When working with complex or uneven surfaces that require flexible reinforcement

• When producing non-structural components or cosmetic layers

• When seeking improved bonding between layers in multi-laminate systems

• When cost efficiency is a priority, as fiberglass mat is typically more affordable

• When using polyester or vinyl ester resins, which are highly compatible with chopped strand mat

Fiberglass mat is also commonly used as a base layer beneath fiberglass cloth to improve resin distribution and reduce print-through of woven patterns on the surface.

However, it is important to note that standard fiberglass mat is not compatible with epoxy resin unless specifically designed for it, due to the binder used in the mat. This factor must be considered during material selection.

Choosing between fiberglass mat and fiberglass cloth ultimately depends on application requirements, mechanical demands, fabrication method, and budget.

If your project requires high tensile strength, stiffness, and structural reliability, fiberglass cloth is the superior choice. It is ideal for load-bearing parts, engineered composites, and applications where performance and durability are critical.

If your priority is ease of handling, mold conformity, cost control, or secondary reinforcement, fiberglass mat provides an efficient and practical solution. In many real-world applications, the best results are achieved by combining fiberglass mat and fiberglass cloth within a single laminate to balance strength, flexibility, and cost.

By understanding the fundamental differences between these two fiberglass materials, manufacturers and fabricators can make informed decisions that improve product performance and long-term reliability.