Fiberglass reinforcement is primarily used to enhance the structural strength of a variety of materials, from plastics and resins to concrete. The embedded fiberglass fibers create a composite that distributes stress more evenly, preventing cracks and deformation under heavy loads. In practical terms, reinforced concrete beams or panels can support larger weights without adding significant bulk, making them ideal for bridges, high-rise buildings, and industrial floors.

In addition to its load-bearing capacity, fiberglass-reinforced materials maintain dimensional stability over time. Unlike metals that may warp under heat or moisture, these composites resist expansion and contraction, which is crucial for precision applications such as aerospace components, automotive body panels, and machinery housings. For buyers, this means materials that last longer and require fewer structural reinforcements, reducing project complexity and cost.

Another critical purpose of fiberglass reinforcement is improving resistance to impact and sudden mechanical stress. Fiberglass fibers act as a network within the matrix material, absorbing energy from impacts and dispersing it throughout the composite. This property prevents localized fractures that often occur in traditional materials like glass or unreinforced plastics.

Applications of this property include automotive parts like bumpers, industrial protective panels, sporting goods, and marine vessels. For example, fiberglass-reinforced boat hulls can withstand collisions with debris or docking impacts without structural failure. Similarly, machinery enclosures benefit from reduced damage from accidental impacts, extending operational life. For end-users, this translates to safer, more reliable products and lower maintenance or replacement costs over time.

Fiberglass reinforcement offers exceptional resistance to corrosion, moisture, and chemical exposure, which makes it a go-to choice in harsh environments. In industries such as chemical processing, wastewater treatment, or offshore structures, traditional metals often degrade quickly when exposed to acids, alkalis, or saltwater. Fiberglass composites, however, do not rust or corrode, retaining their strength and appearance for decades.

Additionally, the non-porous nature of properly manufactured fiberglass prevents absorption of harmful substances, minimizing internal degradation. For businesses, this results in reduced downtime for repairs, lower long-term maintenance costs, and safer operational conditions. This property is especially valued in pipelines, storage tanks, chemical-resistant flooring, and outdoor structural components.

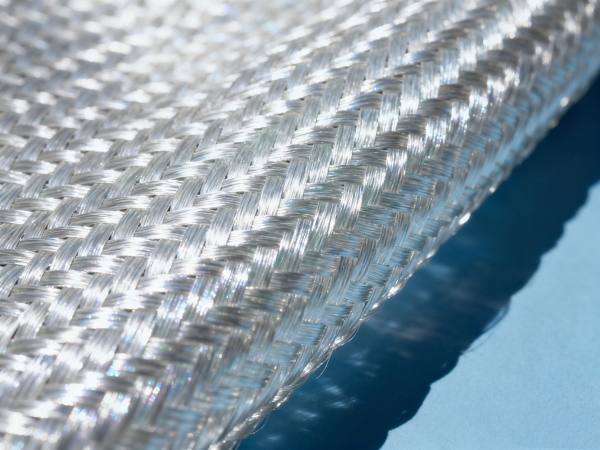

Fiberglass reinforcement enables remarkable design freedom. Its combination of high strength and low weight allows engineers to create large or complex shapes without compromising structural integrity. Fiberglass composites can be molded, cut, and layered into virtually any form, from curved panels to intricate custom parts.

This flexibility is particularly useful in construction and industrial manufacturing. For instance, custom ducting, architectural panels, or specialized equipment housings can be produced more efficiently and with fewer constraints than using metals or solid plastics. The ability to integrate fiberglass into various resin systems also allows designers to optimize performance for specific needs, such as heat resistance, electrical insulation, or UV protection. For buyers, this versatility means products can be tailored exactly to project requirements, reducing material waste and assembly challenges.

Durability is one of the most compelling reasons to use fiberglass reinforcement. By providing resistance to impact, corrosion, and environmental stress, fiberglass composites significantly extend the lifespan of products and structures. This longevity reduces the frequency of repairs, replacements, or downtime, which is a critical factor for cost-conscious industries.

In sectors like construction, transportation, and manufacturing, long-term cost savings are amplified because fiberglass-reinforced materials maintain performance under repeated stress. For example, reinforced panels in industrial plants or bridges can remain operational for decades without major maintenance. For companies and end-users, investing in fiberglass-reinforced solutions means achieving high performance while lowering lifecycle costs, making it both an economical and strategic choice.