As someone who has worked with fiberglass materials for over a decade, I can confidently say: fiberglass composites are far more than “just glass and resin.” At their core, they are engineered materials, meticulously designed to combine tensile strength, flexibility, and corrosion resistance. Unlike metals that corrode or plastics that warp under heat, a well-made fiberglass composite maintains performance under demanding conditions. In my experience, their unique balance of weight and strength makes them indispensable in industries ranging from marine vessels to custom automotive components.

From years in the workshop, I’ve learned that the secret to a high-quality fiberglass composite lies in attention to both fibers and resin:

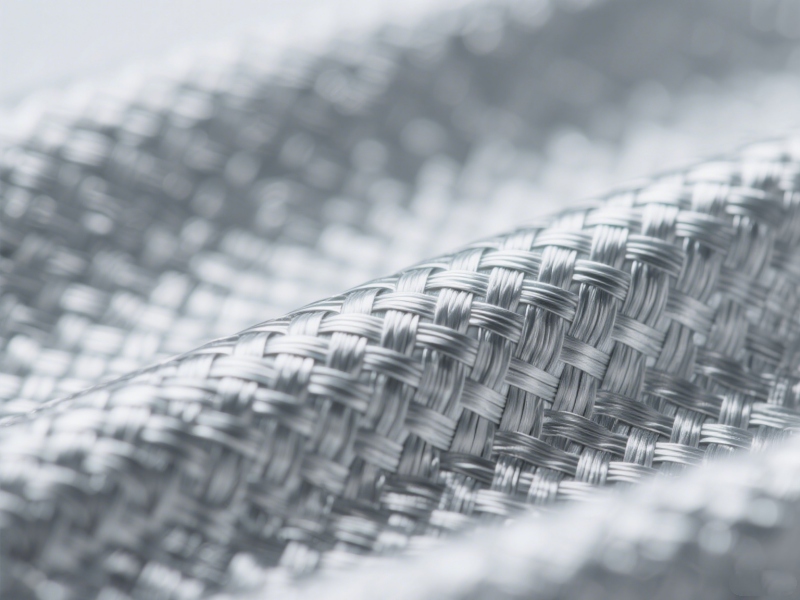

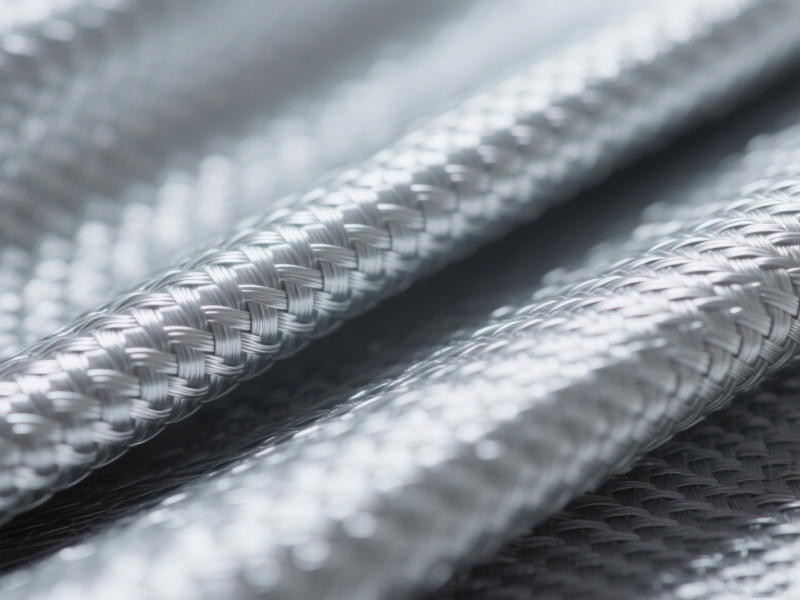

Fiberglass Reinforcement:

Not all fibers are created equal. Woven fabrics, chopped mats, or continuous fibers each bring distinct properties. Proper fiber selection and orientation are crucial—this is where many manufacturers cut corners, but it’s also what separates a durable composite from a brittle one.

Resin Matrix:

Polyester, epoxy, or vinyl ester resins each interact differently with fibers. Over the years, I’ve seen epoxy offer unmatched chemical resistance, while polyester is the workhorse for cost-effective applications. The resin not only binds fibers but also protects them from moisture, UV exposure, and mechanical stress.

Typical Manufacturing Processes I’ve Used:

Hand Lay-Up: Allows precise fiber placement for custom parts.

Pultrusion: Perfect for strong, continuous profiles.

Compression Molding: Efficient for high-volume production with uniform strength.

A key insight I always emphasize: fiber alignment, resin penetration, and curing are the pillars of a reliable composite. Even the most premium fibers fail if poorly processed.

Over the years, I’ve handled almost every variant. Here’s what I’ve learned about their differences:

My advice: choose the type based on application stress, exposure environment, and long-term durability, not just price.

In my experience, the most telling applications reveal the material’s real value:

When I consult clients, I always stress: understanding the material’s strengths and limitations ensures long-term satisfaction. Fiberglass composites are versatile, but only when used intelligently.

After years of hands-on experience with fiberglass composites, I can say this with confidence: they are a fusion of art and science. Mastering fiber selection, resin compatibility, and manufacturing process is key. For anyone looking to invest in these materials, knowledge of composition, type, and practical application is invaluable. Done right, fiberglass composites offer durable, lightweight, and cost-effective solutions unmatched by conventional materials.