Sandwich panels are widely used in marine, construction, transportation, and industrial applications due to their excellent strength-to-weight ratio. While face sheets and core materials often receive most of the attention, fiberglass core mat plays a critical but sometimes underestimated role in overall panel performance. From structural reinforcement to manufacturing efficiency, fiberglass core mat significantly influences how sandwich panels behave in real-world conditions.

In sandwich panel construction, fiberglass core mat is typically placed between the core material—such as foam, balsa, or honeycomb—and the outer skins made of fiberglass-reinforced composites. Its primary role is not to act as a load-bearing core, but rather as a functional reinforcement layer that improves stress transfer and structural integrity.

Fiberglass core mat serves as a transition layer that bridges differences in density, stiffness, and surface texture between the core and the laminate skins. By doing so, it helps distribute stresses more evenly across the panel structure, reducing localized stress concentrations that could otherwise lead to premature failure. In practical terms, this means sandwich panels that are more tolerant of impact, vibration, and long-term mechanical loads.

One of the most important uses of fiberglass core mat in sandwich panels is its contribution to shear strength. Shear forces are primarily carried by the core, but effective load transfer between skins and core is essential for the panel to function as a single structural unit.

Fiberglass core mat enhances this load transfer by creating a reinforced resin-rich zone that improves adhesion and mechanical interlocking. When the panel is subjected to bending or compressive forces, the core mat helps distribute shear stresses more uniformly across the interface. This is particularly valuable in applications such as marine decks, wall panels, and vehicle floors, where panels experience repeated loading and dynamic stresses.

As a result, sandwich panels incorporating fiberglass core mat often demonstrate improved fatigue resistance and higher tolerance to off-axis loads compared to panels without this reinforcement layer.

Delamination is one of the most common failure modes in composite sandwich panels. Poor bonding between skins and core can lead to a dramatic loss of stiffness and structural performance. Fiberglass core mat directly addresses this issue by improving interlaminar bonding.

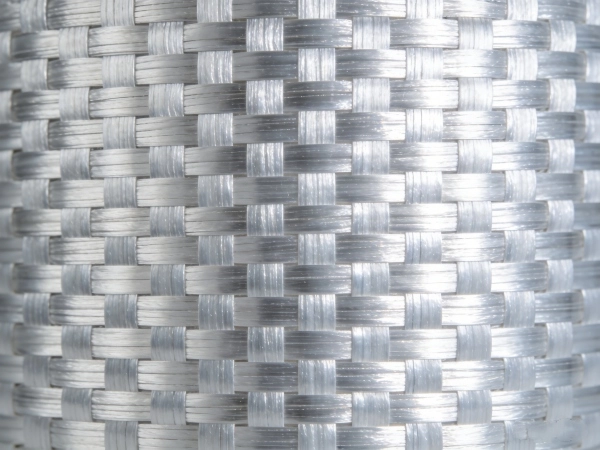

The open, three-dimensional fiber structure of core mat allows resin to penetrate deeply during lamination or infusion. Once cured, this creates a strong mechanical bond that ties the laminate skins to the core more effectively. Compared with smooth core surfaces bonded directly to woven fabrics, core mat provides a larger bonding surface area and better stress distribution at the interface.

This enhanced bonding is especially important in high-humidity or thermally demanding environments, where differential expansion and contraction can place additional stress on adhesive interfaces.

From a manufacturing perspective, fiberglass core mat offers clear processing advantages. Its porous structure significantly improves resin flow and wet-out, particularly in vacuum infusion, RTM, and hand lay-up processes.

The mat acts as a flow medium, allowing resin to move laterally across the panel and penetrate complex core geometries. This reduces the risk of dry spots, voids, and incomplete wet-out—common defects that can compromise mechanical performance. Faster and more uniform resin distribution also leads to more consistent laminate thickness and improved surface quality.

For manufacturers, these benefits translate into shorter cycle times, lower scrap rates, and more predictable production outcomes, all of which are critical in high-volume sandwich panel manufacturing.

Not all fiberglass core mats are the same, and selecting the right type is essential for achieving optimal sandwich panel performance. Key selection factors include areal weight, thickness, fiber orientation, and binder compatibility with the chosen resin system.

Lighter core mats are typically preferred for weight-sensitive applications, while heavier mats may be used where higher shear transfer or surface leveling is required. Compatibility with polyester, vinyl ester, or epoxy resins should also be carefully evaluated to ensure proper wet-out and curing behavior.

Additionally, manufacturers should consider the intended application environment—such as moisture exposure, temperature variation, and mechanical loading—to ensure the selected fiberglass core mat aligns with long-term durability requirements.