Fiberglass core materials play a crucial role in various industries due to their unique combination of strength, lightness, and versatility. Widely used in the manufacturing of composite materials, fiberglass cores provide structural support, improve durability, and offer resistance to harsh conditions. This article will explore the basics of fiberglass core, its role in composite materials, comparisons with other core materials, and its diverse applications across industries.

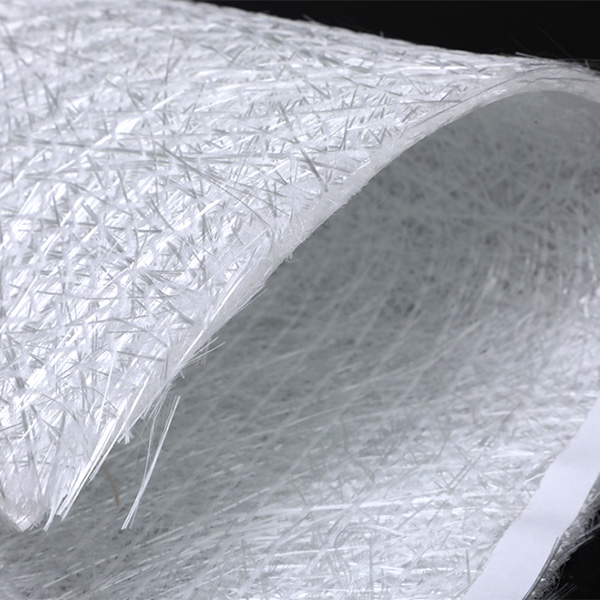

Fiberglass core refers to a central layer of fibrous glass materials, often embedded between two other layers of materials, forming a composite structure. The core is typically made from a highly durable resin-infused fiberglass, which is woven or pressed into sheets. This combination of fiberglass and resin creates a material that is lightweight yet strong, offering an optimal balance between weight and structural integrity.

Fiberglass core materials can be categorized into two types: solid and honeycomb. Solid fiberglass cores are denser and more rigid, while honeycomb cores feature a cellular structure that offers improved strength-to-weight ratios, making them ideal for applications where both strength and weight reduction are important. This core is often chosen for its ability to withstand high pressure, corrosion, and extreme temperatures, making it suitable for industries ranging from aerospace to construction.

In composite materials, fiberglass core serves as the central structure that supports outer layers of various materials, such as carbon fiber or resin-infused cloth. The combination of these layers results in materials that offer superior strength, durability, and resistance to external stresses. The core material itself is lightweight but strong, enabling composite products to maintain structural integrity without adding unnecessary weight.

The role of fiberglass core in composites is pivotal in creating high-performance products. In industries like aerospace, automotive, and marine, composite materials that use fiberglass cores offer significant weight savings compared to metals, while maintaining or even surpassing their strength and durability. These materials can be engineered for specific properties, such as enhanced stiffness or resistance to fatigue, making them invaluable in applications where performance is critical.

Fiberglass core materials are often compared to other common core materials, such as foam, balsa wood, and aluminum honeycomb. Each of these materials has its own set of advantages and drawbacks, and the choice between them depends largely on the specific needs of the application.

In comparison, fiberglass core materials offer an excellent balance of weight, strength, and cost, making them a popular choice across a variety of industries.

Fiberglass cores are utilized in a wide range of applications, owing to their unique combination of properties. Some of the most common industries and uses include:

Carbon Fiber RTM Core Mat Fiberglass Core Flow Mat

Fiberglass core materials are a fundamental component in the production of composite materials used across a wide range of industries. Their combination of strength, lightweight, and resistance to environmental factors makes them an ideal choice for applications where performance is critical. Whether it’s in aerospace, automotive, marine, or construction, fiberglass cores provide an effective solution to enhance product performance while reducing weight. By understanding the unique properties and applications of fiberglass core, industries can make informed decisions to leverage this versatile material for optimal results.